- Home

- Spin Mop Systems

Spin Mop Systems Manufacturer & OEM Supplier

We manufacture spin mop systems for household and commercial cleaning, supporting multiple bucket mechanisms (foot pedal / hand press), durable handles, and refill programs for bulk supply and private label.

Factory-direct supply focused on consistent fiber quality, repeatable performance and stable bulk production for OEM programs.

What Are Spin Mop Systems?

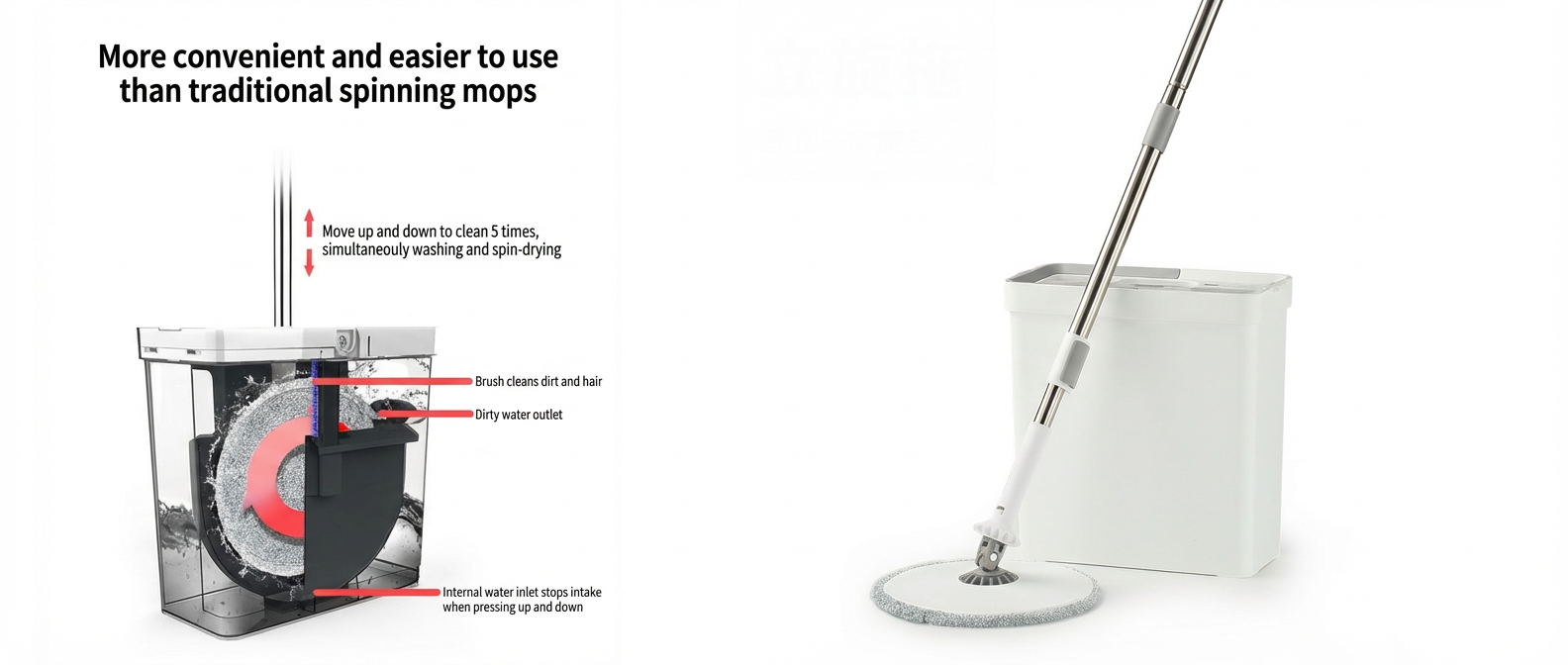

Spin mop systems combine a mop handle + replaceable mop head with a spinner bucket for rinsing and wringing. Compared with traditional mops, spin systems help reduce hand contact with dirty water, improve wringing efficiency, and support refill-based programs for repeated purchase.

Why Spin Mop Sets Sell Well

A complete set is easy for retail and e-commerce: bucket + mop + refills. It also supports a long-term refill strategy for mop head replacements.

- Set-ready SKUs for supermarkets, marketplaces, and wholesalers

- Refill repeat sales microfiber head replacement programs

- Wringing efficiency spinner basket helps reduce dripping

Spin Mop System Structure

A stable spin mop system is determined by the bucket mechanism, spinner basket durability, mop head connection, and handle joint strength. We support component-based customization for your SKU positioning.

1) Bucket & Spinner Mechanism

Choose the wringing method and bucket layout to match your market and target cost.

- Foot pedal spin consumer-friendly and widely accepted

- Hand press spin compact, fewer moving parts

- Drain plug / wheels for convenience and heavier sets

2) Mop Head & Connection

Mop head design impacts cleaning performance and refill compatibility.

- Microfiber yarn absorbent and floor-friendly

- Connection formats thread / click / plate (varies by model)

- Refill packaging single pack or multi-pack options

3) Handle & Joint Durability

Handle stability improves user experience and reduces after-sales issues.

- Material stainless steel / aluminum / coated steel

- Telescopic options length range for different markets

- Grip & printing logo printing and ergonomic grip

Types of Spin Mop Systems We Manufacture

These are common configurations used for OEM programs. We can adjust bucket size, mechanism structure, accessories, and packaging based on your channel (retail / online / B2B).

Foot Pedal Spin Mop Set

Classic retail set with foot pedal spinning. Good for mainstream markets and higher perceived value.

- Best for supermarkets, hypermarkets, large marketplaces

- Options drain plug, wheels, splash guard

Hand Press / Push-Down Spin Mop

Compact system with simplified structure. Suitable for cost-sensitive or space-saving positioning.

- Best for value line SKUs, e-commerce bundles

- Options bucket volume, basket reinforcement

Specification Reference

Below are typical ranges for spin mop systems. Final specs can be customized per your SKU target (mechanism, materials, accessories, and packaging).

| Item | Options | Typical Range | Customization |

|---|---|---|---|

| Bucket type | Foot pedal / Hand press / Dual chamber | 10–20L (varies by design) | Color, structure, drainage, wheels |

| Spinner mechanism | Pedal drive / Press down / Hybrid | Standard to heavy-duty | Material reinforcement, basket style |

| Mop head | Microfiber yarn / Blended yarn | Refill diameter & density configurable | Label, stitching, density, color |

| Handle | Stainless steel / Aluminum / Coated steel | Telescopic 100–140cm | Grip, thickness, printing, joints |

| Packaging | Color box / Kraft / Bulk carton | 1 set per box (common) | Artwork, inserts, barcodes |

| Accessories | Extra heads, drain plug, wheels | Optional | Bundle design for retail strategy |

Quality & Manufacturing

We focus on stable assembly, spinning performance, and packaging durability for long-distance shipping.

Assembly Reliability

Stronger joints, consistent tolerances, and validated bucket structures reduce after-sales issues.

Material Control

Material selection for buckets, spinner baskets, and handles ensures durability and stable spinning.

Packaging Protection

Drop-resistant packing options, clear manuals, and labels for smoother retail distribution.

Mop Head Materials & Refill Programs

Refill compatibility is critical for long-term product performance and repeat sales. We can develop matching refills with different yarn density and stitching structure.

Microfiber Yarn Heads

Widely used for strong absorption and floor-friendly cleaning.

- Density options standard / high-density

- Color options white, gray, custom dyed

- Packaging single refill / multi-pack retail

Refill Strategy for Your Market

Bundle refills in sets or sell separately to improve total sales.

- Starter set 1–2 refills included

- Retail refill pack 2/3/4-pack for shelf display

- B2B bulk master carton for wholesalers

See: Spin Mop Refills

Applications & Target Markets

Spin mop systems are widely used in household daily cleaning and commercial maintenance programs. Choose configuration and packaging to match your channel and consumer behavior.

Retail Chains

Complete set SKUs with color boxes, clear instructions, and optional refills.

E-commerce & Marketplaces

Bundle strategies: extra refills, compact packaging, and differentiated colors.

B2B / Janitorial Supply

Heavy-duty options, bulk cartons, and stable replenishment for refills and accessories.

OEM & Private Label Spin Mop System Manufacturing

We support OEM/ODM programs including logo printing, packaging artwork, SKU planning, and stable mass production for long-term supply contracts.

Customizable Items

Build a market-fit SKU with component-level customization.

- Bucket color, structure, volume, drain plug, wheels

- Mechanism pedal/press design, reinforcement

- Handle material, length, grip, logo printing

- Refills yarn density, stitching, packaging

How to Get an Accurate Quotation

Please share your key requirements so we can recommend the right baseline model.

- Bucket type foot pedal / hand press / dual compartment

- Target positioning value / mainstream / premium

- Order quantity estimated sets + refills

- Packaging color box / kraft / bulk

FAQ

Common questions from B2B buyers about spin mop OEM/ODM programs.

Typically customizable: bucket color/structure, wringing mechanism type (pedal/press), mop head material and density, handle material/length, logo printing, packaging artwork, and bundle configuration (extra refills, wheels, etc.).

Yes. We can support color box/kraft box designs, instruction manuals, barcode labels and carton marks for shipping and retail.

Yes. Many buyers start from existing bucket and mop head structures and then customize colors, logo, packaging, and refill programs.

Bucket type (pedal/press), bucket volume preference, mop head style, handle material/length, packaging requirement, target market/country and estimated order quantity.

Start Your Spin Mop Project with a Manufacturer

Share your target SKU, market channel and packaging needs. We will recommend a suitable baseline configuration and provide sampling/quotation support.

Recommended to Include

- Bucket mechanism foot pedal or hand press

- Set volume bucket size preference

- Refill plan single refill / multi-pack

Optional Accessories

- Wheels / drain plug for heavier sets

- Extra handles spare parts supply

- Packaging inserts manuals, hang tags

You can link to accessories later: Handles & Accessories · Buckets