- Home

- Sponge Mop Systems

Cotton Mop Systems Manufacturer & OEM Supplier

We manufacture cotton mop systems designed for heavy-duty wet cleaning, offering high absorbency mop heads, durable handles, and stable bulk supply for commercial and industrial markets.

Factory-direct supply focused on durable mop heads, repeatable quality control, and OEM/private label programs for bulk orders.

What Are Cotton Mop Systems?

Cotton mop systems use natural or blended cotton yarn mop heads to deliver high water absorption and effective wet floor cleaning. They are widely used in traditional cleaning programs where durability, rinseability, and water handling capacity are required.

Where Cotton Mops Work Best

- Wet mopping tasks high water absorption and rinseability

- Large-area cleaning cost-effective for daily programs

- Industrial environments durable yarn construction

Key Benefits of Cotton Mop Systems

Cotton mops remain a stable choice in B2B cleaning markets. Their absorbency and durability make them suitable for heavy-duty wet cleaning programs requiring repeated rinsing and long-term use.

High Water Absorption

Effective for wet cleaning where water handling capacity and rinseability matter.

Durable Yarn Construction

Designed for repeated washing and long-term use in commercial cleaning workflows.

Cost-Effective Bulk Supply

Suitable for large-area cleaning programs and stable procurement planning.

Types of Cotton Mop Systems We Manufacture

Cotton mop systems can be classified by yarn construction and mop head connection designs. Below are common types we support for wholesalers, distributors and private label programs.

Clamp Type Cotton Mop

Clamp type cotton mop are designed for professional and institutional cleaning programs. The adjustable jaw clamp securely holds cotton mop heads, allowing quick replacement and stable performance during wet mopping tasks.

Plastic Gate Clamp Cotton Mop

Plastic gate clamp cotton mop offer a lightweight and cost-effective solution for routine cleaning tasks. The plastic gate opens from the side, allowing cotton mop heads to slide in easily and be secured by a rotating plastic nut, making installation quick and user-friendly.

Frame & Tie Cotton Mop

Frame and tie cotton mop use a flat support frame with tie-on cotton mop covers. The mop head is secured to the frame using straps, providing wide surface coverage and stable performance for large-area floor cleaning tasks.

Twist & Self-Wringing Cotton Mop

Twist and self-wringing cotton mop feature a built-in twisting mechanism that allows users to squeeze excess water by pulling and rotating the handle. This design improves efficiency during wet cleaning and reduces manual effort, making it suitable for household and light commercial use.

Cotton Mop Head Materials & Yarn Options

Yarn selection and construction determine absorbency, durability and lint performance. We provide flexible options to match target market requirements and private label specifications.

Yarn Material Options

- Natural cotton yarn traditional absorption and cleaning

- Blended cotton yarn balanced durability and cost

- Color-coded yarn supports hygiene zoning programs

Banding & Construction Options

- Tail band / loop band reduces tangling and improves coverage

- Weight & size ranges confirmed based on programs and markets

- Connection designs screw type, clamp type, custom fitting

Applications & Target Markets

Cotton mop systems are commonly used where high absorption, rinseability and durability are required for repeated wet cleaning. We support buyers supplying commercial, industrial and institutional cleaning programs.

Commercial Cleaning

Daily wet cleaning in offices, retail and facility maintenance where absorbency and durability matter.

Industrial Facilities

Heavy-duty wet cleaning tasks in workshops and factories where strong yarn construction is preferred.

Healthcare & Food Service

Cleaning programs requiring zoning, repeat washing and stable consumable supply planning.

OEM & Private Label Cotton Mop Manufacturing

We support OEM and private label programs with flexible yarn options, mop head construction choices and packaging solutions. Send your required mop head weight, connection type and target market for evaluation.

Customization Options

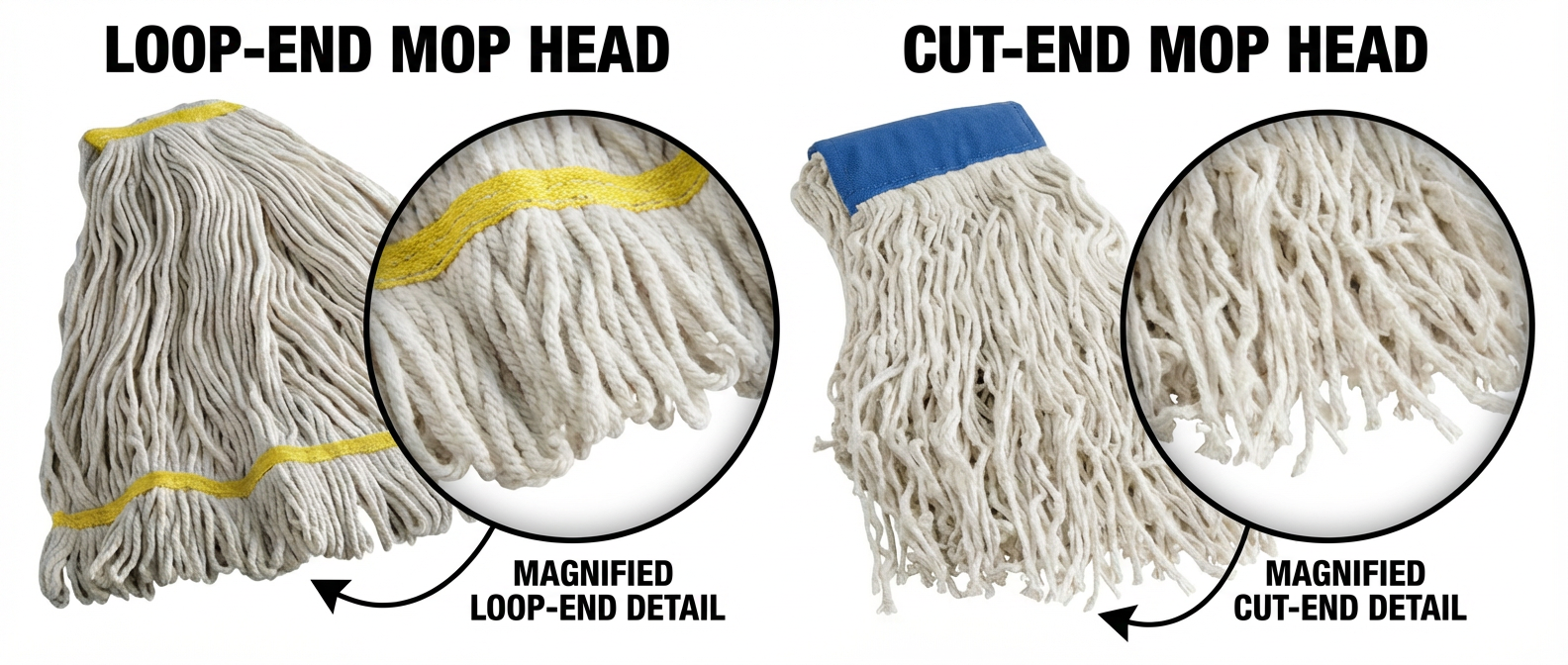

- Mop head type cut-end / loop-end / tailored constructions

- Yarn material & color cotton or blended, zoning colors

- Connection design screw type, clamp type, custom fitting

- Branding & packaging logo, label, barcode, retail packs or bulk cartons

Quality Control

Checks on yarn materials, construction consistency, weight tolerance, and final packing for stable batch supply.

Bulk Supply Support

Production planning for repeat orders and long-term programs, supporting distributors and wholesalers.

Project Communication

Fast response for samples, specs confirmation and packaging development for private label programs.

FAQ

Common questions from B2B buyers sourcing cotton mop systems, cotton mop heads and private label programs.

We are a manufacturer supplying mops, mop heads and refills for global B2B markets. We support OEM/private label programs and stable bulk supply.

Cut-end mops are economical and highly absorbent for standard programs. Loop-end mops are designed to reduce linting and improve durability for longer service life.

Yes. Weight and size options are available based on target market requirements. Please share your preferred specifications and estimated quantities.

Yes. Color-coded yarn and band options can support hygiene zoning programs in healthcare, food service and facility cleaning.

MOQ and lead time vary by model and customization. Standard items may support trial orders; OEM programs typically require higher MOQs. Lead time is usually 15–30 days after confirmation.

Please include mop head type (cut-end/loop-end), weight range, connection type (screw/clamp), handle requirements and target market. Photos or samples help confirm compatibility.