- Home

- Sponge Mop Systems

Sponge Mop Systems Manufacturer & OEM Supplier

We manufacture sponge mop systems designed for wet cleaning, featuring different squeezing mechanisms and sponge material options for bulk supply and private label programs.

Factory-direct production focused on consistent quality, stable bulk supply, and OEM/private label support.

What Are Sponge Mop Systems?

Sponge mop systems are wet-cleaning solutions using a sponge-based mop head to absorb water and remove liquid spills efficiently. Compared with flat mops or string mops, sponge mop systems are known for strong water pickup and convenient wringing mechanisms.

Key Benefits

- Strong water pickup for wet cleaning and spill removal

- Efficient wringing mechanisms roller / lever squeeze designs

- Refill-friendly designs support replacement and repeat orders

Sponge Mop System Structure

A complete sponge mop system typically includes three key parts. This section highlights the system-level components—helping buyers confirm the right design direction before OEM development or bulk sourcing.

Handle & Pole System

Available in different lengths, materials and locking designs to meet retail and commercial programs.

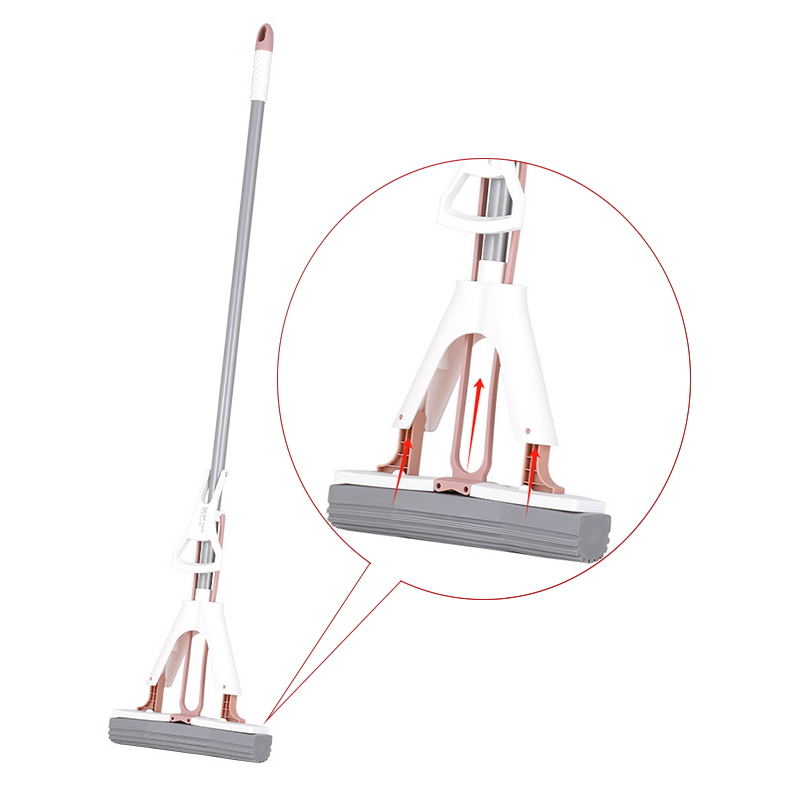

Wringing / Squeezing Mechanism

Lever squeeze, roller squeeze or other mechanical structures for efficient water removal and better control.

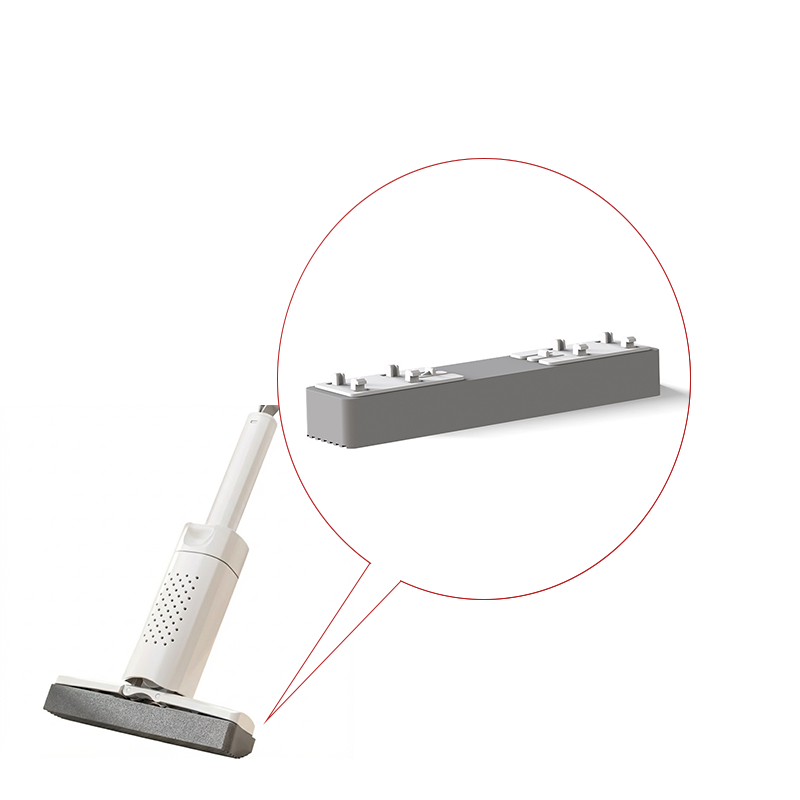

Sponge Mop Head

The working component responsible for absorption and contact cleaning, often designed for easy replacement. Looking for refills? View Sponge Mop Heads

Types of Sponge Mop Systems We Manufacture

Sponge mop systems can be classified by wringing mechanism and replacement structure. Below are common system types we support for OEM and bulk supply.

Roller Sponge Mop Systems

Roller designs help squeeze out water effectively and are widely used for daily wet cleaning programs.

Lever-Squeeze Sponge Mop Systems

Lever mechanisms provide easy wringing with stable control, suitable for routine cleaning and retail supply.

Double Roller Sponge Mop Systems

Double-roller structures improve wringing efficiency and are often selected for higher-frequency wet cleaning scenarios.

Replaceable Sponge Head Mop Systems

Designed for long-term use with refill replacement programs, supporting repeat purchases and stable supply.

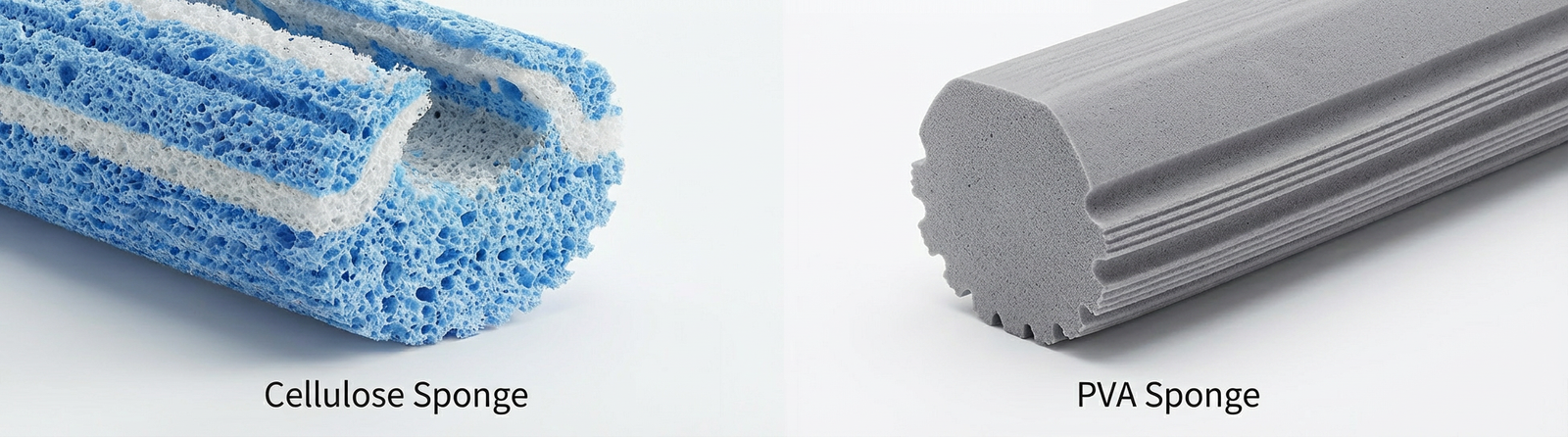

Sponge Material Options

We offer different sponge material options to match performance and cost requirements. For sponge mop systems, material selection is one of the key factors affecting absorption, durability and drying behavior.

Standard Sponge Options

Designed for general wet cleaning and stable bulk supply. Suitable for standard programs and cost-sensitive markets.

- Balanced absorption for daily wet mopping

- Stable supply for consistent bulk ordering

PVA Sponge Options

Available for buyers seeking higher absorbency and faster drying performance. Specifications can be confirmed based on target market and system design.

Explore PVA Mops

- Higher absorbency

for demanding wet cleaning - Fast drying behavior

supports replacement programs

Note: PVA is a specialized sponge option within the sponge mop category. Contact us to confirm suitable solutions for your market.

Applications & Target Markets

Sponge mop systems are commonly used for wet cleaning tasks where liquid pickup and wringing efficiency matter. We help buyers choose suitable designs based on floor types, usage frequency and preferred wringing mechanisms.

Home Cleaning

Kitchen, bathroom and daily wet mopping programs requiring quick water pickup and easy wringing.

Commercial Cleaning

Shops, offices and hospitality environments where consistent wet cleaning performance is required.

Retail Programs

Standard models and refill replacement plans for stable long-term supply and repeat purchases.

OEM & Private Label Sponge Mop System Manufacturing

We support OEM and private label projects with flexible customization options—covering structure, materials and packaging. Send your target mop model, sponge head dimensions or reference samples for evaluation.

Customization Options

- Mop system design roller / lever squeeze / replacement structure

- Sponge head options material, size, refill mechanism

- Branding & packaging logo, color, box, label, barcode

- Supply support bulk planning, stable QC, repeat orders

Quality Control

Inspections across material input, assembly, functional performance and final packing to ensure consistency.

Bulk Supply

Stable production planning to support long-term programs and repeat orders for global B2B buyers.

Project Support

Fast communication for sampling, specification confirmation, and compatibility evaluation.

FAQ

Common questions from wholesalers, brand owners and distributors sourcing sponge mop systems and refill programs.

We are a manufacturer specializing in mops, mop heads and replacement refills. Production covers material processing, assembly and packaging to support bulk supply and OEM projects.

Yes. We support system structure selection, sponge head sizing, color/logo branding and packaging customization for OEM/private label programs.

Yes. We support refill-oriented system designs and replacement programs. Please share sponge head dimensions or reference samples for evaluation.

Please send your existing mop head dimensions, photos, and any model information. Our team will help confirm a compatible refill direction. You can also visit our

We offer standard sponge options for general wet cleaning and PVA sponge options for higher absorbency and faster drying requirements. Final selection depends on market needs and system design.

MOQ and lead time vary by model and customization. Standard items may support trial orders; OEM projects typically require higher MOQs. Lead time is usually 15–30 days after confirmation.

Start Your Sponge Mop Project with a Manufacturer

Tell us your requirements, and we will help with product selection, structure confirmation, OEM options and bulk pricing.

Helpful Links

•View All Sponge Mops

•Sponge Mop Heads & Refills

•Explore PVA Mops